1. Description of pasteurizing milk processing line

The processing line produce several types of market milk products, i.e. whole milk, skim milk and standardized milk of various fat contents.

Pasteurized milk is milk which has been heat-treated to kill pathogens which cause disease. Not all pathogens are removed during the pasteurization process, so pasteurized milk is not 100% sterile, but many people consider it to be safer to drink than raw milk which has not been pasteurized at all. The bulk of the milk sold in commercial grocery stores is pasteurized, and much of it is also homogenized to prevent the cream from separating.

First the milk is preheated and standardized by in line milk fat standardization system. The purpose of standardization is to give the milk a defined, guaranteed fat content. Common values are 1.5% for low fat milk and 3% for regular grade milk, fat contents as low as 0.1 and 0.5 % is skim milk.

Then the standardized milk is homogenized. The purpose of homogenization is to disintegrate or finely distribute the fat globules in the milk in order to reduce creaming. Homogenization may be total or partial. Partial homogenization is a more economical solution, because a smaller homogenizer can be used.

The milk, now is pumped to the heating section of the milk heat exchanger where it is pasteurized. The necessary holding time is provided by a separate holding tube. The pasteurization temperature is recorded continuously. Pump is a booster pump which increases the pressure of the product to a level at which the pasteurized product cannot be contaminated by untreated milk or by the cooling medium if a leak occur in the plate heat exchanger. If the pasteurization temperature should drop, this is sensed by a temperature transmitter. A signal activates flow diversion valve and the milk flows back to the balance tank. After pasteurization the milk continues to a cooling section in the heat exchanger, where it is regeneratively cooled by the incoming untreated cold milk, and then to the cooling section where it is cooled with ice water. The cold milk is then pumped to the filling machines.

Temperature and pasteurization holding time are very important factors which must be specified precisely in relation to the quality of the milk and its shelf life requirements. The pasteurization temperature is usually 72 – 75℃ for 15 – 20 sec. A common requirement is that the heat treatment must guarantee the destruction of unwanted microorganisms and of all pathogenic bacteria without the product being damaged.

2. Features of pasteurizing milk processing line

Advanced technology and energy saving.

SUS304/316L material,high qualified component of international brand.

Semi-automatic as well as fully automatic system available.

Customized turn-key solution including installation, commissioning at your side.

The finished product quality is excellent, and the color is delicious.

High productivity, flexible production, can be customized according to customer demand.

Complete supervision system, equipped with control room to monitor each processing stage.

Daily output can be clearly revealed.

3. Specification of pasteurizing milk processing line

|

Raw material |

liquid cow milk, goat milk, camel milk |

|

Capacity |

500~15000L/H |

|

Product packages: |

Gable top carton; glass bottle; plastic pouch; paper pouch; etc. |

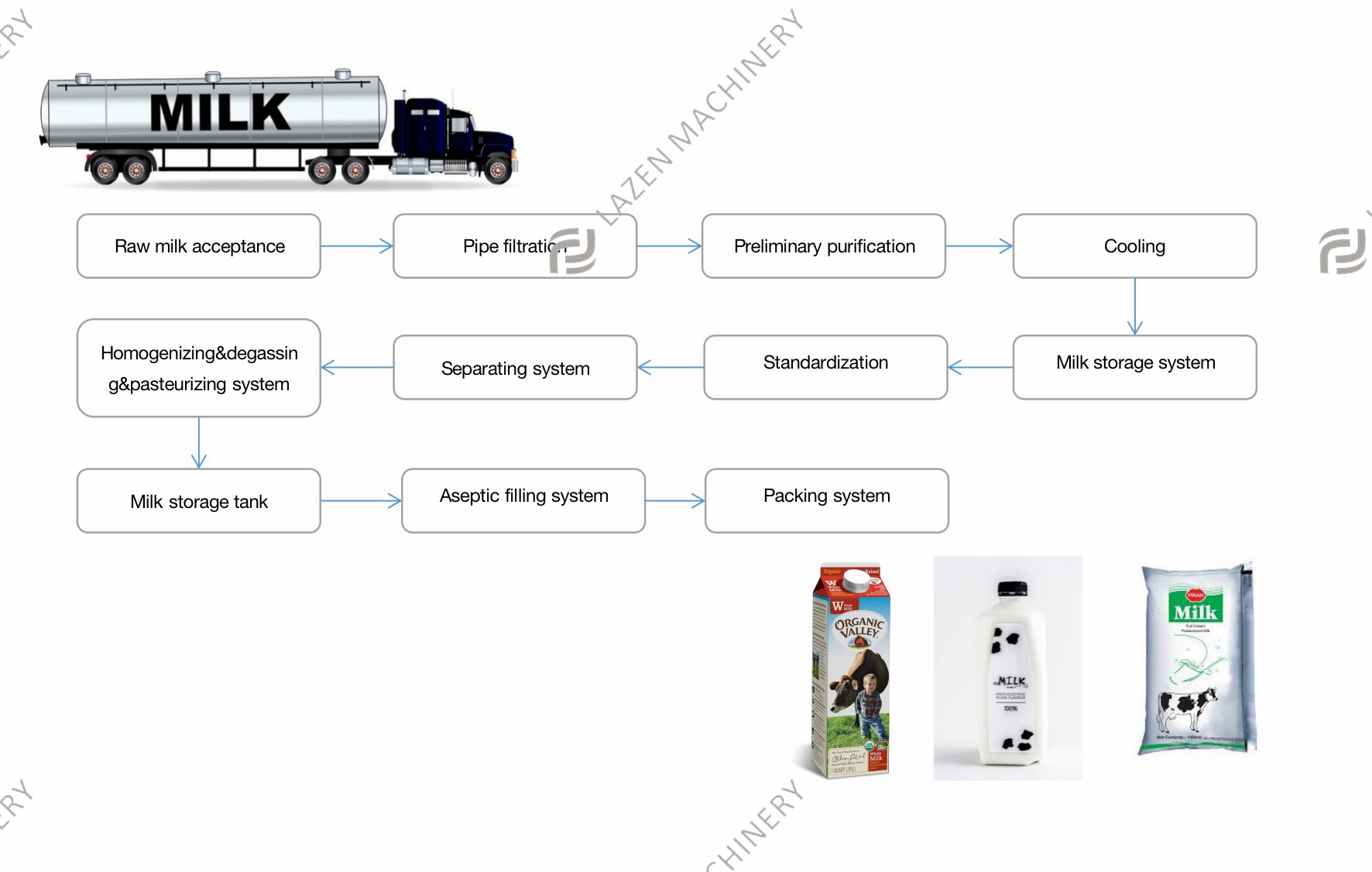

4. Flowchart of pasteurizing milk processing line

5. End package

6. Reference pictures of pasteurizing milk processing line

Milk powder processing line

Milk powder processing line UHT Milk Processing Line

UHT Milk Processing Line Ice cream processing line

Ice cream processing line