1. Description of fruit wine and vinegar processing line

Almost all seasonal fruits and vegetables with high sugar content can be fermented to make fruit wine or fruit vinegar.

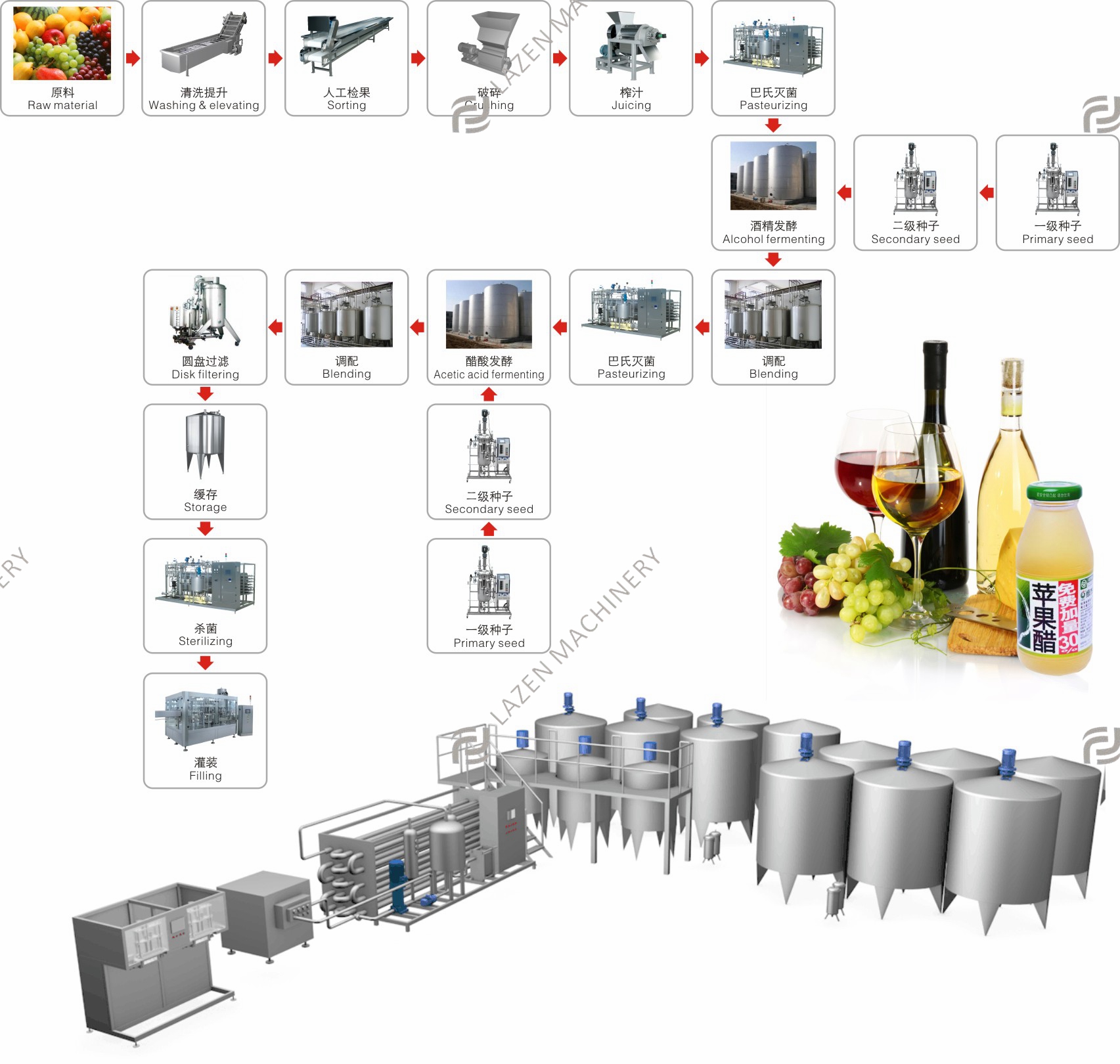

The fruit wine and vinegar processing line mainly includes: washing and sorting system, juice extracting system, enzymatic hydrolysis and filtration system, mixing and blending system, alcohol fermentation system, acetic acid fermentation system, clarification and storage system, blending and sterilization system, finished product filling and packing system, auxiliary energy system.

Fruit wine and vinegar processing line capacity is from 10tons/day-480tons/day.

2. Features of fruit wine and vinergar processing line

Advanced technology and energy saving.

SUS304/316L material,high qualified component of international brand.

Semi-automatic as well as fully automatic system available.

Customized turn-key solution including installation, commissioning at your side.

The finished product quality is excellent, and the color is delicious.

High productivity, flexible production, can be customized according to customer demand.

Complete supervision system, equipped with control room to monitor each processing stage.

Daily output can be clearly revealed.

3. Specification of fruit wine and vinegar processing line

|

Hammadde |

Elma, üzüm, portakal, çilek, çilek, alıç, muz, vb |

|

Tamamlanmış ürün |

Şarap, meyve sirkesi içecek |

|

Kapasite sınıfı |

10 to 480tons/day |

|

Meyve şarabı |

Fermente içecekler, damıtma şarap, köpüklü şarap |

|

Meyve sirkesi |

tatlar türleri |

|

Paket seçenekleri |

Halka-çekme can / Tetra Pak / cam şişe / plastik su ısıtıcısı |

|

Tasarım kapasitesi |

müşteri ihtiyaçlarına göre |

4. Flowchart of fruit wine and vinegar processing line

5. End package

6. Reference pictures of fruit wine and vinegar processing line

Fruit juice processing line

Fruit juice processing line Beverage processing line

Beverage processing line Bitkisel çay içecek işleme hattı

Bitkisel çay içecek işleme hattı