1. Description of grape processing line

The fresh grape can proceed into concentrated grape pulp, NFC grape juice, grape clear concentrate juice and red wine through fermentation according to clients different requirements.

Grape juice processing line includes fresh grape washing and sorting system, grape destemmer and crusher system, grape juice extracting system, enzymatic hydrolysis and filtration system, evaporating system,sterilizing system, aseptic filling system, auxiliary energy system,etc.

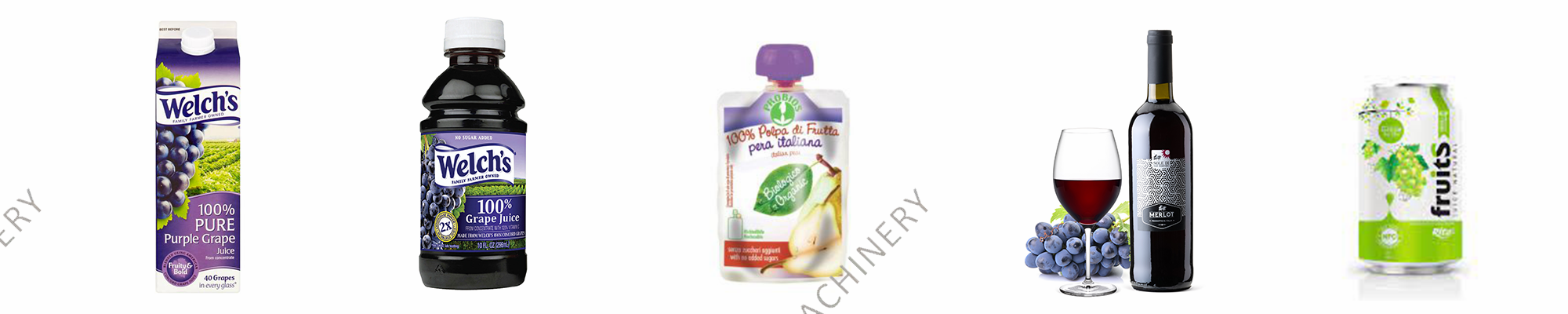

The grape processing line capacity is about 30tons to 480 tons per day, the end products can be filled into bottles, metal cans, carton boxes, pouches or bulk containers.

Grape juice yield: about 50%(50% for the peels and seeds for the waste.

Raw material solid content: 16~20birx, final concentrate juice concentration:about 65~72brix.

2. Features of Mango Processing Line

Advanced technology and energy saving.

SUS304/316L material,high qualified component of international brand.

Semi-automatic as well as fully automatic system available.

Customized turn-key solution including installation, commissioning at your side.

The finished product quality is excellent, and the color is delicious.

High productivity, flexible production, can be customized according to customer demand.

Complete supervision system, equipped with control room to monitor each processing stage.

Daily output can be clearly revealed.

According to the characteristics of easy oxidative discoloration and heat sensitivity of grapes, our equipment adopts a fully enclosed and cold pressing method to obtain grape juice during the juice extraction process to ensure the optimum products.

3. Specification of grape pro cessing line

|

Xom ashyo |

yangi uzum |

|

tayyor mahsulot |

Grape pulp, NFC juice, clear concentrate juice and red wine |

|

sig'im |

30~480tons/day |

|

sharbat hosil |

About 50% |

|

Boshlang'ich shakar kontent |

16`20Brix |

|

Terminal shakar kontent |

65~72Brix |

|

Mahsulot qadoqlash |

Aseptic bag / can / bottle /tetra pack/doypack/pouch bag |

4. Flowchart of grape processing line

5. End package

6. Reference pictures of grape processing line

Ehtiros meva ishlash liniyasi

Ehtiros meva ishlash liniyasi Mango ishlash liniyasi

Mango ishlash liniyasi Fig ishlash liniyasi

Fig ishlash liniyasi Berry meva ishlash liniyasi

Berry meva ishlash liniyasi Tsitrus ishlash liniyasi

Tsitrus ishlash liniyasi Guava processing line

Guava processing line